Final Project

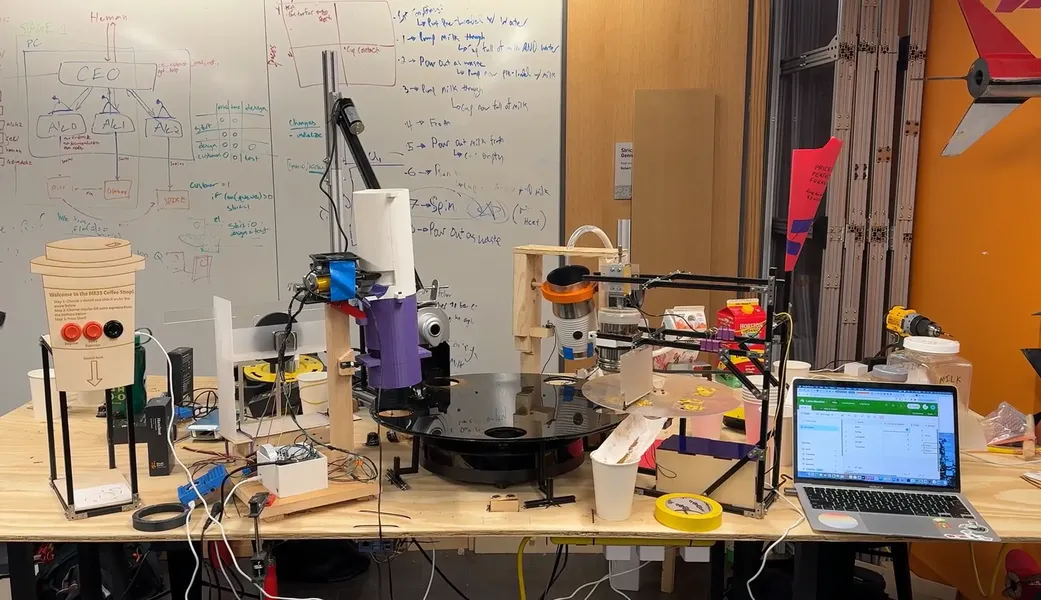

For the final project of ME-35, intro to robotics, we, as a class were tasked with creating an automated latte dispensing machine. The specifications required that a customer be able to order 1 of 2 sizes: medium or large, in addition to a unique artistic design which would be imprinted on the drink. The drink would be made and presented to the customer.

Planning

This project was class directed, and as such all planning and logistics was handled and decided on by the entire class. Through our discourse we decided to break up the project into 4 groups:

- Coffee: Responsible for creating the coffee and dispensing it into the cup

- Milk: Responsible for frothing the milk and dispensing it into the cup

- Art: Responsible for adding the unique artistic design to the latte

- Transport: Responsible for the transportation of the Cup to each station and to the customer, as well as setting up the interface for which all groups communicate their status and other info

These groups worked amongst themselves during the week, but came together during class time to discus integration and "global" objectives. This system worked well and lead to great communication.

My Part

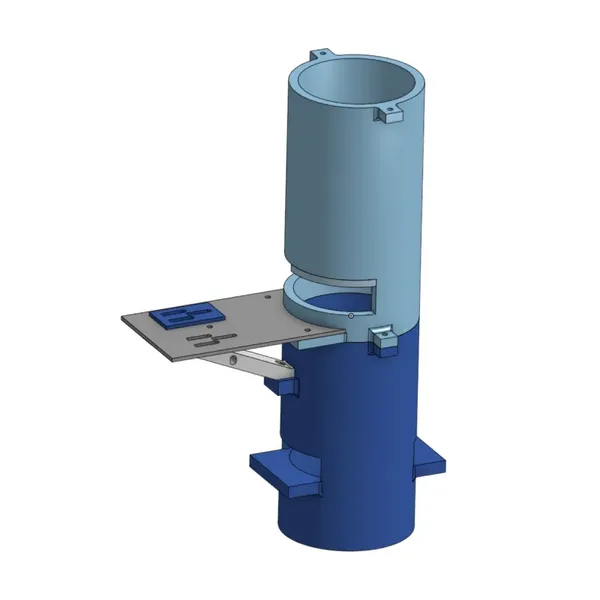

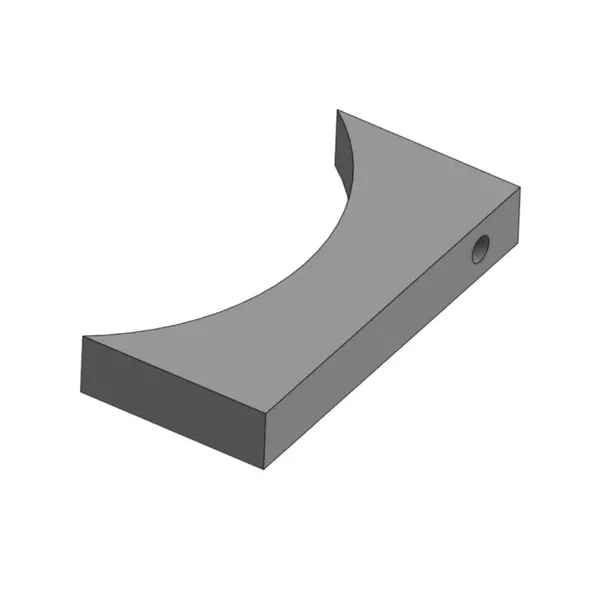

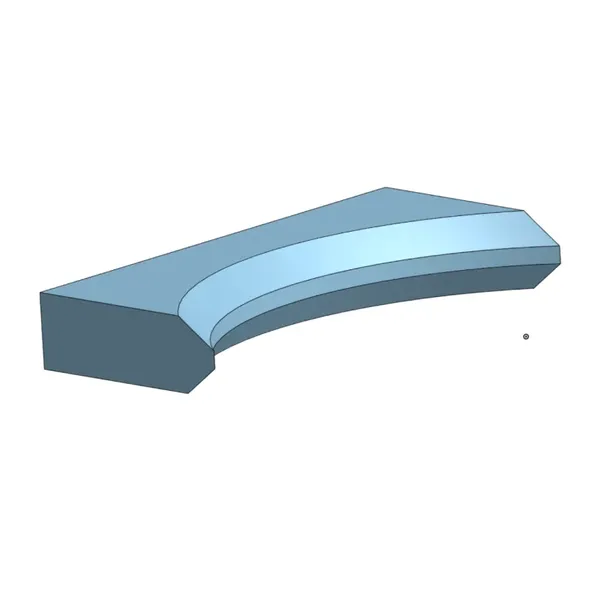

I was apart of the transport group and was responsible for creating the cup dispenser. This mechanism needed to be able to take a stack of cups and drop them one at a time onto the transport system, when a new order was placed. While researching I came across a design involving 2 solenoids and thought it was great to adapt to this project. The design is made up of a "separator" and a "holder". Each is a solenoid with a different attachment for the specific role. First the holder is actuated and serves to hold the stack of cups in place. When a cup needs to be dispensed, the separator is actuated and the holder is released. This releases the bottom cup while keeping the top supported. Then the mechanism returns the original state where now each cup has advanced 1 position.

With this design selected, I started to model the tube that would hold the cups. I added cut outs and supports for mounting the solenoids. Additionally, I modeled the solenoid end attachments for the holder and separator. The plan was to laser cut as much as possible and 3D print the more complex objects. This optimized for speed and rapid prototyping.

Building & Testing

Building the assembly went on relatively smoothly apart from some minor design changes to the 3D models. During testing is when the problems started to show. Some of the major issues included: the cups not being released, cups not being separated, high solenoid friction, PWM not working as anticipated, and solenoid heating issues. I did my best to quickly pivot my original design decisions around these problems, but that could not be done in all cases. For example: since PWM does not work well on solenoids, as they are essentially inductors, this lead to heating issues from the holder solenoid. This is because it is left in the on state when ever the mechanism is stalled, which encompasses most of the operational time. Additionally PWM does not work, thus it must be left on 100%, using all 12V of equivalent current. The solenoids I had also only had 1 polarity, meaning I could not have the rest position for the holder be the extended state. In this case I just had to deal with this issue the best I could. With retrospect I would of had to use a digital to analog converter and a amplifier circuit to remedy this issue.

The First Success

I had resolved most of the issues and had a working result.

Full Team Integration & Testing

By this time all the groups had mostly working machines. The Coffee group had retrofitted a preexisting coffee dispenser and automated the pod insertion and removal, as well as the dispensing. The Milk group had done a similar thing with a consumer milk frother, using tubes and pumps to fill it and a rotating system to empty it. The Art group had made a spinning wheel with multiple designs that could be chosen from where by cinnamon would take on the form of the desired shape. The wider Transport group had made a turntable design where the cup would be delivered to each station by rotation. Additionally, they created a system for integrating each machine together on a service called AirTable. This was so each groups computing device could signal one another of their status. At this time to finish up my product I needed to program my system with the AirTable service. Just as before testing this time round came with its own set of issues, but this time for the entire system. These were handled to the best of our ability.

Results

The success criteria for this project was to be able deliver 3 lattes with out human interaction. On the day of the Demo we proved successful in getting 1 latte before the system failed. Although we did not meet our success criteria, I still believe the effort and learning experience involved made it a win no matter what.